PC800 Shear Control Upgrade

- Increased productivity through programming and machine operation

- Intuitive interface

- Fast set-up and operation

- Plain English Diagnostics

Learn More

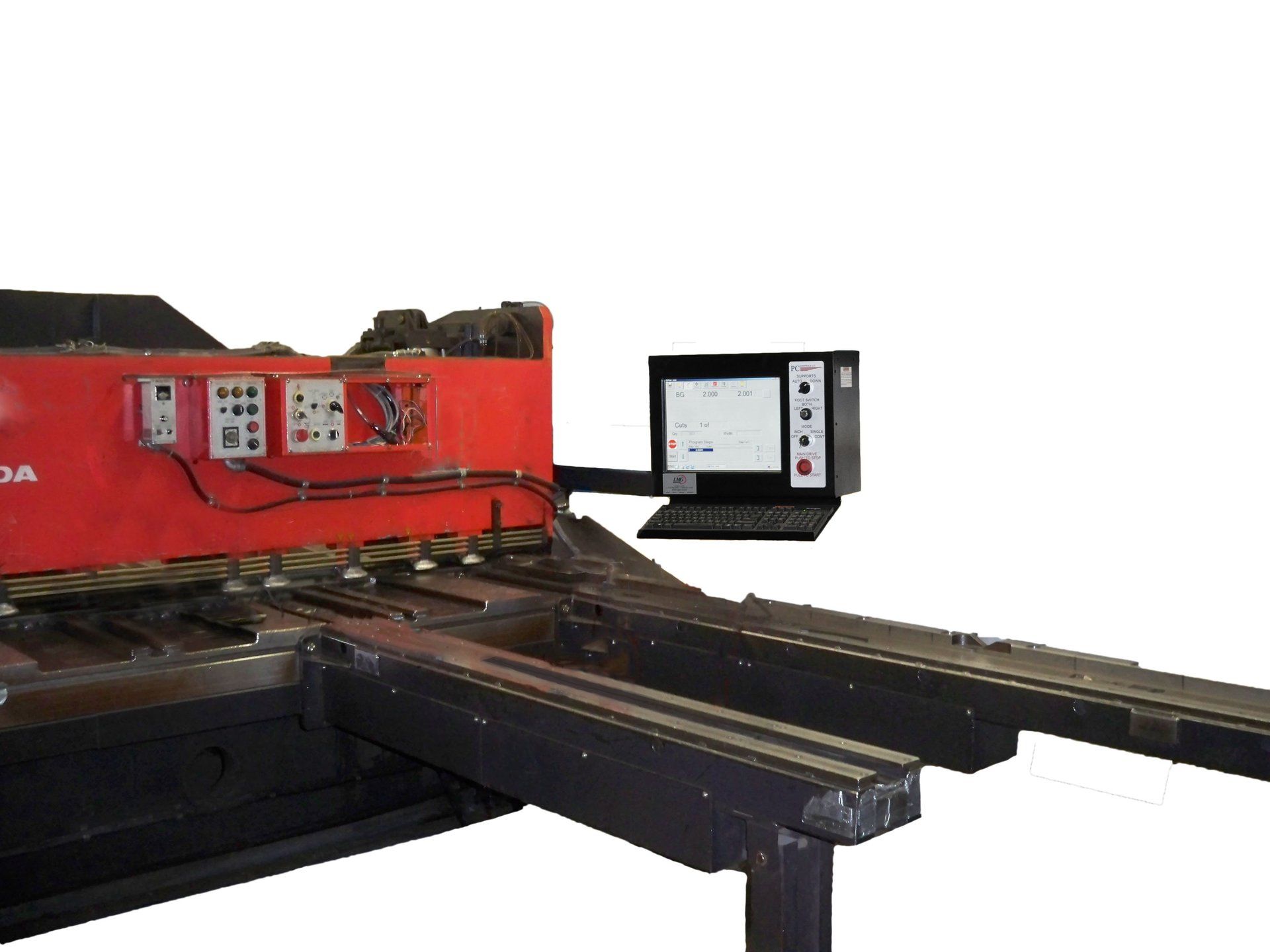

**CNC Shear Control Upgrade with PC Controls' PC800 Shear System**

The **PC800 Shear Control Upgrade** by PC Controls is revolutionizing the metal fabrication industry with its advanced CNC shear control technology. Designed specifically for precision and ease of use, this **PC-based CNC upgrade** modernizes outdated shear equipment to enhance productivity, accuracy, and user control. This webpage details the exceptional capabilities of the PC800 upgrade, crafted for manufacturers looking to improve operational efficiency, reduce machine downtime, and simplify diagnostics with intuitive, user-friendly software.

### Advanced Features for Enhanced CNC Shear Performance

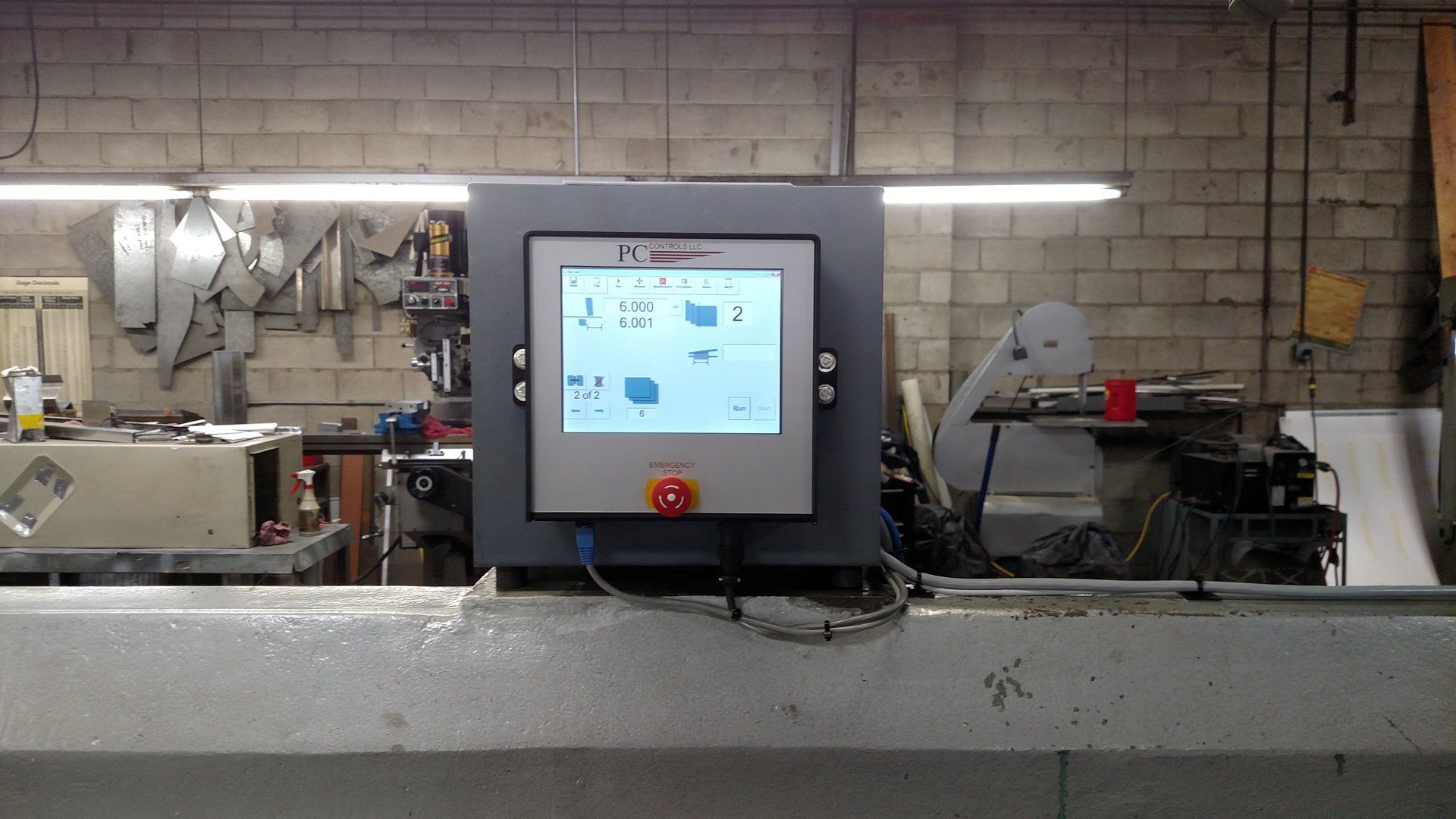

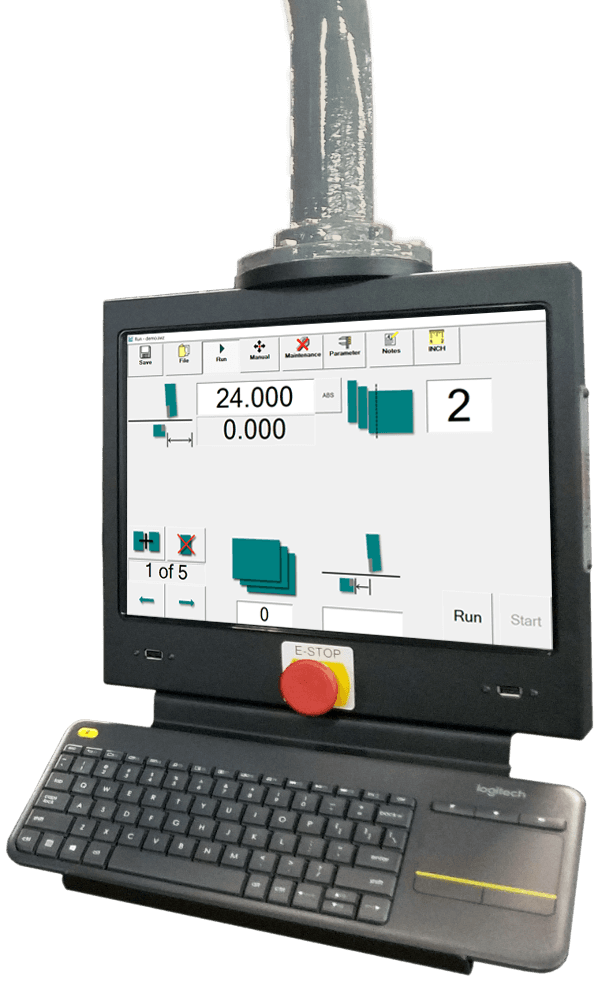

The PC800 Shear Control Upgrade incorporates cutting-edge **CNC control technology** that integrates seamlessly with your factory’s existing operations. Key features include an industrial-grade **15- or 19-inch color touchscreen**, licensed **Microsoft Windows 10 Professional (64-bit)** software, and high-speed processing capabilities thanks to a **solid-state hard drive** starting at 256GB, 4GB DDR3 RAM, and an Intel Core series processor. This CNC shear control solution allows operators to perform complex cutting tasks with ease and accuracy, transforming old shear machines into high-performance CNC equipment without the cost of replacing the entire machine.

### Benefits of the PC800 CNC Shear Control Upgrade

PC Controls has optimized the PC800 Shear Control Upgrade for productivity and reliability, providing a robust CNC control system that extends the life of metal shears and minimizes maintenance. This upgrade is perfect for facilities looking to improve their fabrication efficiency with high-tech **CNC shear machine upgrades**. The **Shear Wizard Programming Software** included in the package allows for efficient job setup, instant diagnostic feedback, and effortless operation, making it an invaluable addition to any modern factory.

#### 1. **Increased Productivity and Performance**

The PC800 Shear Control Upgrade’s CNC software offers operators precise control over every cut, ensuring clean, accurate shearing that minimizes waste and maximizes throughput. The intuitive **touchscreen control panel** simplifies job configuration, enabling operators to focus on production quality. Additionally, the **Intel Gigabit Ethernet network interface** provides reliable, high-speed connectivity for seamless data transfer between the CNC control system and your facility’s network, making production and data management a breeze.

#### 2. **User-Friendly Interface with Touchscreen Controls**

The **15- or 19-inch color touchscreen** is an advanced feature that makes the PC800 Shear Control system easy to operate. This interface is designed to reduce user error and improve productivity by providing quick access to settings and tools, allowing operators to efficiently manage each task. PC Controls understands the importance of a well-designed control interface, and the touchscreen is crafted to be both responsive and durable, essential for a factory setting.

#### 3. **Durability and High-Performance Hardware**

Built to withstand the demands of an industrial environment, the PC800 Shear Control Upgrade includes a solid-state hard drive for fast data access and an **Intel Core series processor** to handle complex tasks with ease. With 4GB of DDR3 RAM, the system processes large job files without lag, supporting the production speed and accuracy that manufacturing environments demand. This hardware configuration ensures that your CNC shear machine operates reliably, even during peak production.

#### 4. **Seamless Integration and Quick Installation**

The PC800 Shear Control Upgrade is designed to integrate easily with existing shear machines, minimizing installation downtime. By transforming outdated CNC shears into fully modernized, PC-controlled equipment, the upgrade offers a cost-effective solution for manufacturers seeking to increase machine lifespan without investing in new hardware.

### Shear Wizard Programming Software for CNC Shear Machines

The **Shear Wizard Programming Software** that accompanies the PC800 upgrade provides an advanced level of functionality, enabling easy setup, precise control, and efficient diagnostics. This software is crucial for minimizing setup time, allowing operators to program jobs quickly and adjust cutting parameters to fit specific materials or production requirements. **CNC shear programming** with Shear Wizard is both intuitive and powerful, with diagnostic capabilities that enable operators to identify and resolve issues before they impact production.

### Why Choose PC Controls for CNC Shear Upgrades?

PC Controls stands out in the CNC industry as a trusted provider of high-quality **CNC machine control upgrades**. With the PC800 Shear Control Upgrade, manufacturers gain access to a robust, reliable system that enhances performance and minimizes maintenance. Whether your facility specializes in small-batch custom work or high-volume production, the PC800 Shear Control Upgrade is designed to maximize efficiency, quality, and uptime. This CNC shear control solution is more than an upgrade; it’s an investment in modern, precision-driven manufacturing technology.

### Optimize Your CNC Shear Control with PC Controls’ PC800

Upgrading your CNC shear machine with PC Controls’ PC800 Shear Control system not only increases productivity but also brings state-of-the-art features to your fabrication processes. Contact PC Controls today to learn how the **PC800 Shear Control Upgrade** can help optimize your operations, improve production quality, and future-proof your manufacturing processes.